Sydney (Australia) invents 100% renewable carbon material BIOCARBON, which can directly replace fossil carbon in steel production in electric arc furnaces (EAF) for decarbonization of the steel industry

BIOCARBON will allow steelmakers to reduce their carbon footprint without incurring large capital costs to modify their equipment or processes, according to Manufacturers Monthly.

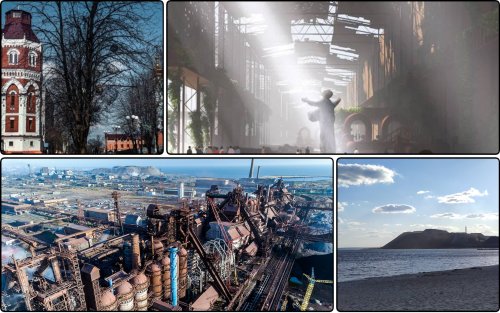

The product has already passed initial testing at EAF Molycop and testing by the University of New South Wales. Commercial testing of the new product is scheduled for May at the Molycop steel plant, located in Newcastle, Australia.

BIOCARBON

The initiative was supported by the Federal Government's Department of Industry, Science, Energy and Resources through an entrepreneurial program that recently provided BIOCARBON with a $ 293,840 grant to accelerate commercialization.

The first test will use 75 tons of renewable carbon product (BIOCARBON brick) to produce 8,500 tons of steel.

The BIOCARBON product is made from low-value wood biomass streams, which are converted into a high-quality carbon product by a thermochemical pyrolysis reaction. The crude product obtained by this process is of high quality with a lower ash content and a higher carbon content than the fossil coke used in the production of EAF steel.

BIOCARBON has issued a preliminary patent for its new approach to transforming this product into a form similar in nature to fossil coke, ie. increase its density and mechanical strength without the use of typical binders, which are not useful for the process of chemical production of steel.

Additional benefits include converting the waste stream into value-added raw materials and reducing the amount of wood waste entering the landfill.

After all, in New South Wales alone, more than 22 million tonnes of wood biomass waste is underused, and this amount of available raw material far exceeds the needs of the EAF sector in Australia.

"Molycop's carbon-renewable carbon test will demonstrate the effectiveness of a product in full-fledged green steel production compared to existing fossil carbon indicators," – said Chad Shepperd, CEO of BIOCARBON.

He also added that BIOCARBON, combined with "green" electricity, will allow the main segment of the steel sector to become carbon neutral with the possibility of 100 percent decarbonization in the future.

After a successful test, BIOCARBON expects to conclude commercial purchase agreements, which will allow businesses to attract investment and scale their production capacity.

"The green technological revolution is happening right here on the North Beaches. We are proud to support companies like BIOCARBON by taking their innovative technologies to the next level through the commercialization process. BIOCARBON not only improves our quality of life through innovative innovation, but also creates new skilled jobs for Northern Beaches and supports our economic recovery, " – said Mackellar member Jason Falinski.

It will be recalled that Australia will spend $50 million on carbon capture and storage centers

As reported by EcoPolitica, experts told how EU policy affects the decarbonization of steel.