In Europe, the steel industry will reduce direct and indirect CO2 emissions in the industry by a third, or 81.5 million tons, thanks to 60 decarbonisation projects planned for this decade.

The capital costs of the projects will be € 31 billion, and their operating costs are estimated at € 55 billion, reports EUROMETAL

This was stated by Axel Eggert, CEO of the Eurofer Steel Association, at the Clean Steel Partnership webinar.

He explained that such high prices are based on uncertainty about the prices of hydrogen and green electricity.

So a ton of green steel could initially be 35-100% more expensive than its blast furnace counterpart, but over time it is expected to become competitive.

To encourage steelmakers to decarbonise the sector, Eurofer proposes to create leading green steel markets and use difference contracts and other risk-sharing instruments. And the introduction of incentives for the use of "green" steel in the following sectors would also stimulate the industry, because end users would feel that they get a bonus when choosing "green steel".

Public procurement and contracts can also play a significant role in creating leading markets, as this share of total EU spending is 20%.

The material noted that metallurgical plants need to make investment decisions on decarbonisation projects by the end of 2022 to achieve their 2030 emissions targets. However, projects are negatively affected by uncertainty due to the lack of transition assistance.

"There are many programs to fund industrial projects, innovations and important projects of common European interest, but although the Clean Steel Partnership is already working well, other schemes remain underfunded or projects are slow or delayed," Egert said.

Decarbonisation is also hampered by uncertainty about access to energy at competitive prices, including electricity and hydrogen. For the EU's metallurgical industry to reach carbon neutrality by 2050, it will need 400 TWh / year of electricity, 230 TWh / year of which will be used to produce 5.5 million tonnes of hydrogen.

Eggert explained that 400 TWh is seven times more than what the steel industry is buying from the grid today, but in the near future this will be a requirement of only one sector that will compete for decarbonized electricity with many others.

"These are huge sums, and the infrastructure is not available at all today, which is a problem for companies when making investment decisions," he said.

Building the necessary infrastructure is becoming even more important in the wake of the Russian-Ukrainian war, as Europe may not be counting on a sufficient supply of natural gas.

"We thought we could use natural gas to help reduce the carbon footprint of blast furnaces, at least until 2030 or later, until hydrogen starts to enter more and more of steel plants, but we will probably need hydrogen much sooner." said Egert.

Blast furnaces generate their own electricity from waste gases, but this will not be the case in the future, given the hydrogen needs of the same gases, which means that plants will receive more electricity from the grid, which also requires major infrastructure measures.

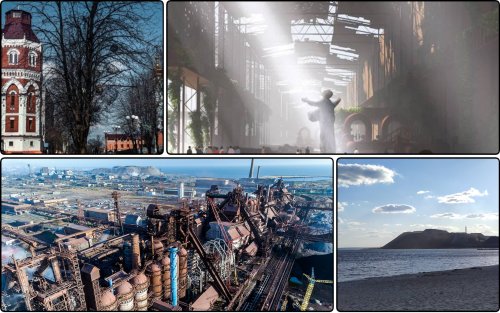

The EU metallurgical industry emits 0.2 gigatonnes of CO2, which is 6% of Europe or 25% of total industrial emissions. Most of them focus on 20 sites, mostly those equipped with blast furnaces, which account for 5% of the EU's CO2 emissions.

Emission reductions of 30% by 2030

The EU metallurgical industry has jointly committed itself to reducing emissions by 30% by 2030 from 2021 and is looking for the most cost-effective ways to do so.

Eurofer calls for free allocation of CO2 emission permits based on greenhouse gas emission benchmarks, compensation for indirect costs and additional carbon adjustments as elements to help make the transition. The association estimates the deficit of free emissions at EU metallurgical enterprises in € 3.5 billion a year, expecting it to grow to 2030 € 13.8 billion a year.

The EU parliament is expected to vote on its proposals soon.

We will remind, Eurofer criticized the intention of the European Parliament change the emissions trading system.

As EcoPoliticа reported earlier, the transatlantic partnership, thanks to collective market power and regulatory influence, can stimulate the reduction of metallurgical emissions sector.