E3G analysts believe that China, as the world's leading steel producer, should become a leader in the greening of the metallurgical sector and reduce emissions in the industry.

Metallurgy is responsible for about 17% of China's emissions and more than 60% of the world's carbon emissions from steel, according to China Dialogues.

China has recently set a number of targets for decarbonisation of steel, backed by several emission reduction measures. But this will not be enough to transform the sector to limit the global increase in average temperature to 1.5 ° C.

So a recent report by the E3G Climate Change think tank and the Pacific Northwest National Laboratory showed that China's steel emissions need to be halved by 2030. However, the Chinese government has recently changed its targets for reaching a peak in emissions from steel production by 2030, rather than 2025, as announced in March 2021.

The paper noted that the transition to cleaner technologies and participation in international initiatives will allow China to remain competitive in future green steel markets, participate in global efforts to set standards for industrial decarbonization and become a leader in greening the global metallurgical sector.

Experts also believe that the current policy is going in the right direction, but too slowly. D For a stable 1.5C path, China's metallurgical sector must reach its peak of emissions as soon as possible, halving emissions by about half by 2030 and by 99% by 2050.

“Thus, the sector's latest guidance on reaching peak emissions by 2030 is far from sufficient. On the contrary, key steelmakers Baowu Steel, HBIS and Baotou Steel, which together account for 17% of China's total production, have set more ambitious goals, ”writes China Dialogue.

Manufacturers aim to reach peak emissions long before 2025, significantly reduce emissions by 2030 and become zero by 2050. The Chinese Metallurgical Industry Association (CISA) also supported a project that proposed reaching a peak in emissions by 2025. These signals from the industry indicate that a faster transition is possible.

The report notes that taking a set of measures to improve the efficiency of materials, together with the expansion of steel processing, could halve emissions from the metallurgical sector in 2050 compared to 2020. After all, instead of producing primary steel, steel scrap can be processed in electric arc furnaces (EAF), which do not require coking coal or iron ore as raw materials.

The simulation showed that scrap-based steel production reduces emissions by about 85% than traditional primary production in blast furnaces. By increasing scrap-based production to 56%, China could reduce steel emissions by 39% compared to 2020 in 2050.

Also Improving the efficiency of materials can reduce global steel emissions by 21% in 2050. These include measures such as life extension, optimized design and recycling of metal-intensive products after use.

To harness the full potential of leverage, concerted policy efforts will be needed to curb primary steel production, stimulate processing, improve the collection and sorting of steel scrap, and extend the life of metal-intensive assets. A recent government "guiding opinion" on the sector has shown progress in helping to increase recycling, setting a target of increasing the use of steel scrap to 300 million tonnes against 260 million tonnes in 2020.

In addition, infrastructure needs to be built using low-emission technologies.

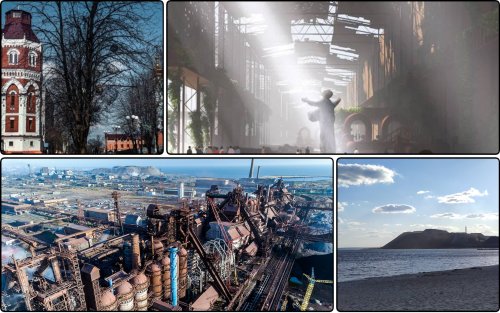

92% of steel in China is currently produced by blast furnaces and basic oxygen furnaces, coal-based plants in which metallurgical coal acts as both a source of heat and carbon in the iron production process. As a result, the metallurgical sector is responsible for more than 30% of total coal consumption in China and is a major source of growing demand for coal.

To achieve the goal of curbing global temperatures to 1.5C, only 10% of China's steel can be produced with such plants, and these furnaces must also be equipped with carbon capture and storage technologies. By 2050, most blast furnace production should be replaced by scrap-based electric arc furnaces combined with green hydrogen-based direct recovery (DRI) production.

In the production of hydrogen-based direct reduction iron (DRI), conventional fossil fuels are being replaced by hydrogen from renewable energy sources. A number of hydrogen DRI pilot projects have been announced in China over the past year. To achieve the required level of emission reductions, it is important that electricity and hydrogen used come from renewable sources to facilitate the phasing out of coal production in the steel sector by 2050.

Although hydrogen-based DRI production in most countries is still in its infancy, the first hydrogen-based industrial DRI plant built by Chinese steelmaker HBIS is expected to open in Zhangjiaku in 2022.

"China will have to significantly accelerate the transition of its capacity to use EAF based on scrap and hydrogen DRI, which will require increased policy support and incentives. In particular, the government should issue clear policy guidelines on decarbonisation, which will increase the processing and efficiency of materials in steel production, as well as accelerate the modernization of China's current production fleet to low-emission technologies, "- said in a statement.

China will also soon have to deal with the effects of carbon taxes, such as the EU's Carbon Border Regulation (CBAM). Chinese officials have repeatedly opposed the CBAM, but the measures could also offer China incentives to speed up internal transition.

For example, steelmakers in China that use low-carbon technologies such as hydrogen-based DRIs have the potential to profit from CBAM.

We will remind, called three key points on the way to reducing carbon emissions in the steel industry.

As EcoPoliticа reported earlier, China's civil aviation will focus on green transition industry.