Scientists at the Max Planck Institute for Iron Research in Düsseldorf, Germany, have developed a new way to extract iron from red mud, or industrial waste from aluminum mining.

The plasma-chemical technology in the laboratory allowed to obtain about 98% of iron from its theoretical limit, Chemistry World reports.

It is noted that the world has accumulated 4.5 billion tons of red sludge and its amount increases by 180 million tons every year. Currently, only 3% of the sludge is processed into ceramics that can be used in construction.

The article emphasized that in addition to iron, red sludge contains yttrium, scandium, cadmium, chromium, and unreacted aluminum oxide.

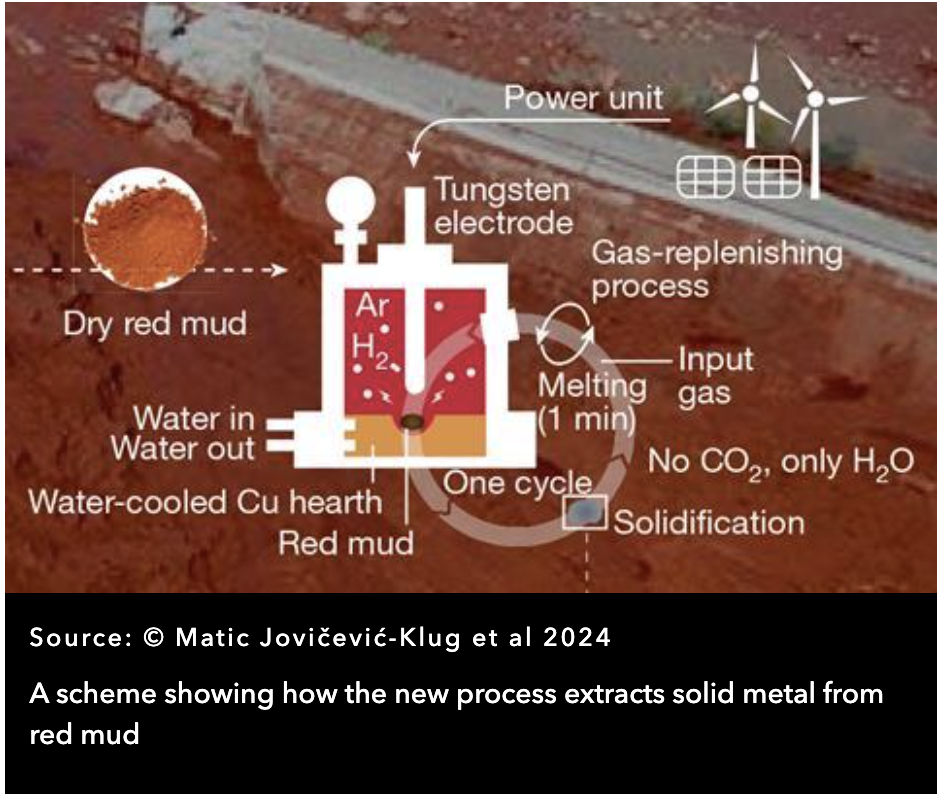

Institute researcher Dirk Raabe explained that the new technology is based on plasma chemistry. The sludge is placed in an electric arc furnace before a mixture of hydrogen and argon is introduced. A 200A discharge is then used to melt the sample and ionize the hydrogen to react with the iron at the same time.

He emphasized that in six cycles in the laboratory it was possible to obtain 2.6 g of metallic iron from 15 g of red sludge. In addition, the iron was "cleaner" than in a typical blast furnace, and was suitable for direct steel production.

According to him, the real breakthrough was the selective recovery of a complex mixed-phase oxide such as red mud and the extraction of a single, nearly pure target product. It is likely that the technology can be extended to the extraction of rare earth elements from red mud.

“The process can be very energy efficient because the reaction between hydrogen radicals and oxides is exothermic. So once the plasma is ignited, the reaction supplies the energy to support the molten oxides, and the only energy needed is electricity to sustain the arc,” Raabe said.

He explained that the use of green energy and hydrogen will make the process carbon neutral. However, using the technology in all of the world's steel plants would require 10,000 times more green hydrogen than is currently available.

Raabe emphasized that in addition to iron extraction, the technology will help make red mud detoxification economically viable.

According to Ray Peterson, director of technology at American aluminum processing company Real Alloy, the technology is impressive, but still far from industrial application. For the process to work, cheap electricity and cheap hydrogen are needed, which are currently unavailable.

"The problem is that you're competing with conventional iron production processes that already exist," Peterson added. ] are likely to be limited."

Earlier, EcoPolitic wrote, that Israeli space startup Helios has invented a technology to produce steel by burning sodium, which can halve energy consumption and completely eliminate direct emissions of carbon.

As EcoPolitic previously reported, the Boston Metal company received $20 million from the World Bank's International Finance Corporation (IFC) for the development of the final technology production of green steel without hydrogen using electrolysis.