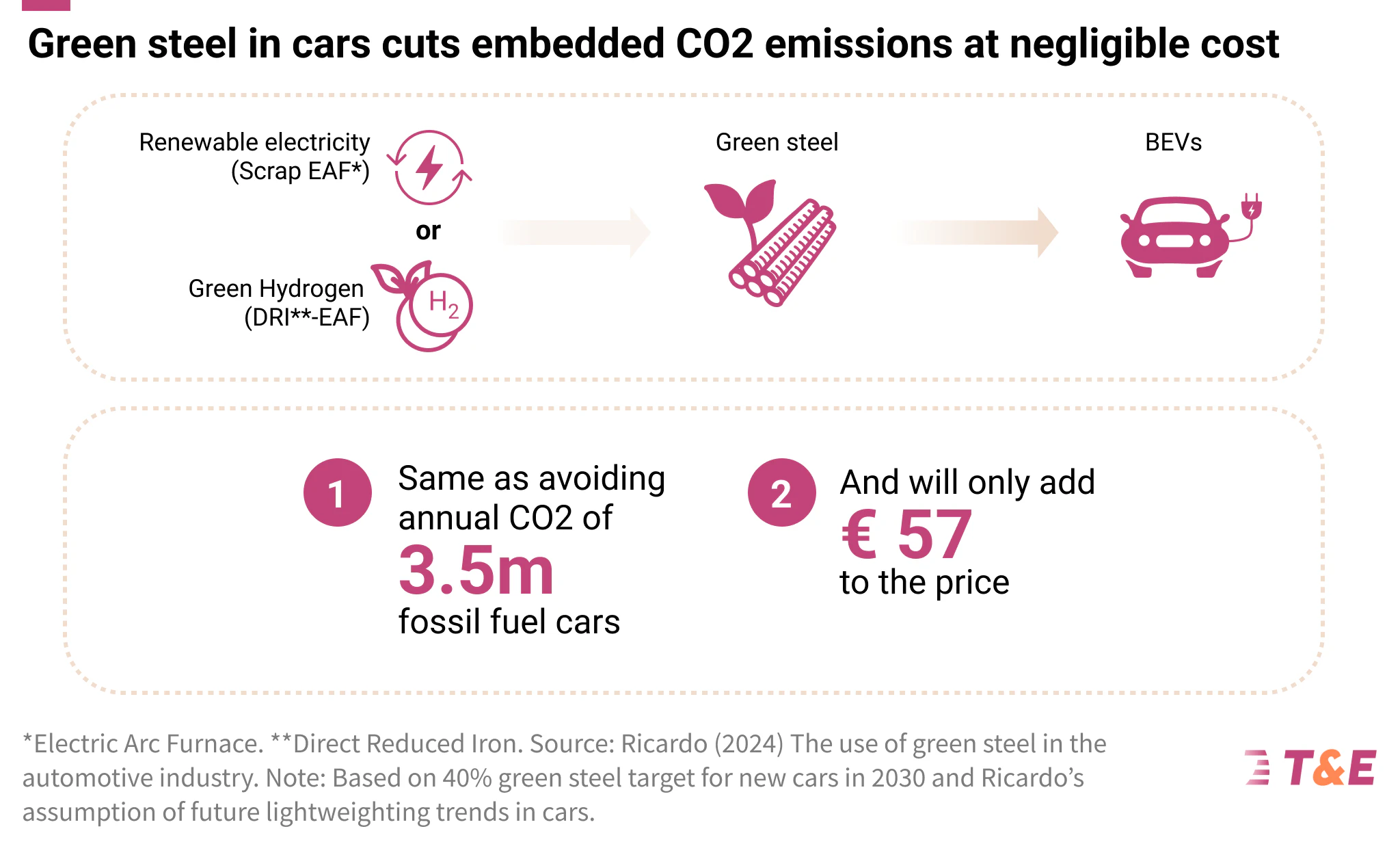

The use of "green" steel in the production of cars is absolutely affordable. So, the use of 40% "green" steel in new cars by 2030 will add only €57 to the price of an electric car with a battery (BEV), by 2035 this increase will decrease to €49, and by 2040 it will be only €8.

Such conclusions were made by the European Federation for Transport and Environment (The European Federation for Transport and Environment – abbreviated Transport & Environment or T&E), based on its own analysis and the results of a study by the consulting company Ricardo.

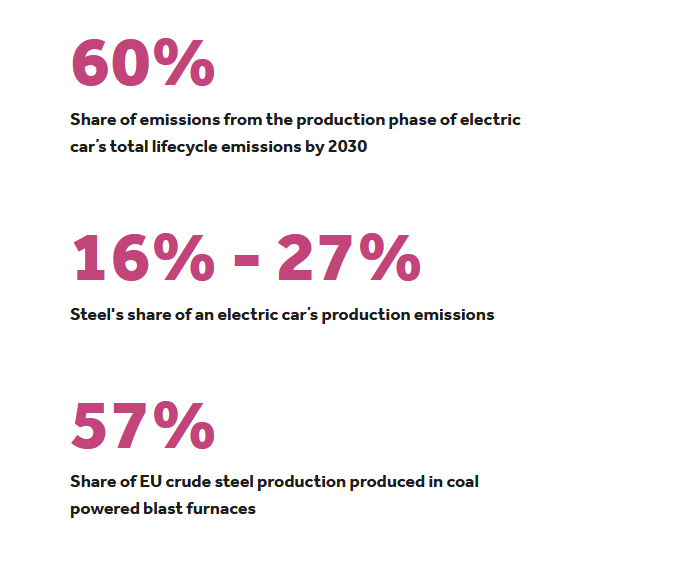

Experts say that since the automotive industry is switching to electric cars, attention to reducing emissions has moved from the exhaust pipe to the production process. They give the following figures:

- by 2030, production emissions will account for about 60% of the total emissions of electric vehicles during their life cycle;

- steel will account for 16% to 27% of these emissions.

Green steel offers significant climate benefits with minimal cost increases, according to T&E's findings. It is produced using "green" hydrogen, direct electrification processes or recycled steel.

According to experts, the automotive sector consumes about 17% of steel in the EU and can stimulate the demand for environmentally friendly steel. They are confident that cars, especially premium models, will cover the short-term costs associated with greener steel production.

It is expected that by 2030, 172 million tons of environmentally friendly steel will be produced in Europe, which will significantly exceed the projected demand of the automotive sector of 21 million tons. Even if the use of automotive steel remains at the level of 2022 (35.7 million tons), there will be more than enough "green" steel.

Benefits for the climate

T&E is confident that switching to environmentally friendly steel can significantly reduce CO2 emissions from car manufacturing. Thus, the use of 40% environmentally friendly steel by 2030 could reduce CO2 emissions by 6.9 million tons, which is equivalent to the annual emissions of 3.5 million fossil-fueled cars.

By 2040, using 100% environmentally friendly steel could reduce emissions by as much as removing 8.1 million internal combustion engine cars from the road. This highlights the enormous climate potential of green steel as manufacturers strive to reduce emissions and achieve net zero.

T&E experts concluded that switching to environmentally friendly steel in car manufacturing offers a practical and cost-effective way to reduce carbon emissions in the automotive sector. And since significant production of "green" steel is planned by 2030 and a minimal increase in costs for consumers, this transition is feasible and necessary to achieve climate goals.

At the same time, the federation's specialists noted that the success of "green" steel requires political support and the following steps:

- Clearly define green steel: Create a pan-European definition of green steel, aligned with the International Energy Agency (IEA) definition of near-zero emissions steel.

- Establish usage obligations: Require automakers to use more sustainable steel in new cars: 40% by 2030, 75% by 2035 and 100% by 2040.

- Improve the quality of recycled steel scrap through measures in the revised ELV Regulation: set mandatory requirements for the quality of recycled steel to meet automotive grade standards, enabling more recycled steel to be used in car production.

As EcoPolitic previously reported, China is accelerating transition to "green" steel, as CBAM is "looming". The volume of reduction of CO2 emissions in the country may amount to 200 million tons by 2026, which is equal to all emissions of the EU steel sector.