Canadian startup CarbiCrete has developed a concrete production technology that uses steel slag and carbon dioxide instead of cement.

The new material is not only environmentally friendly, but also 30% stronger than the standard counterpart, writes Waste360.

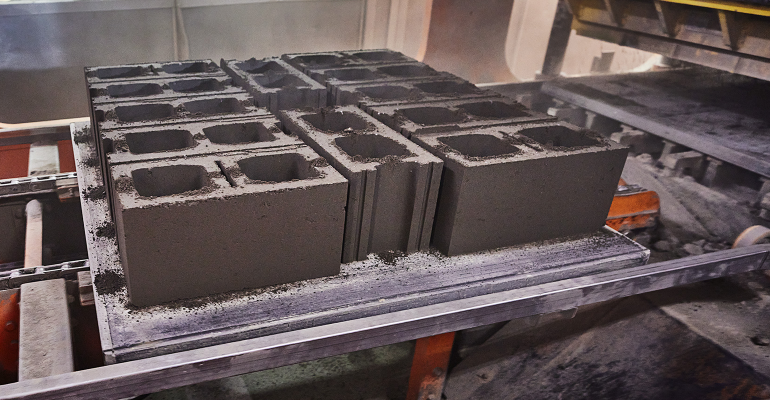

A key feature of the proposed CarbiCrete method was the use of steel waste, which is crushed and mixed with filler and water. The mixture is formed into blocks and placed in an absorption chamber, where the finished bricks are saturated with carbon dioxide.

When CO2 comes into contact with steel slag, a reaction occurs to form calcium carbonates. They act as a binder and give the material strength.

CarbiCrete claims that "carbon" blocks are 30% stronger than conventional concrete when loaded in compression. In addition, they are more resistant to sudden changes in temperature, better endure freeze and thaw cycles.

Most importantly, such eco-concrete reduces the level of environmental pollution. According to the authors of the project, the innovation will capture up to 20 tons of CO2 per day.

Consequently, the company launched a pilot project to produce 450 tons of concrete (25,000 bricks) per day.

It is noted that the use of production waste will also reduce production costs by 10-20%, while the cost of conventional cement is almost $200 per ton.

Before EcoPolitica wrote that Scottish startup Kenoteq launches K-Briq — building bricks, which are 90% construction waste. Innovative brick retains heat better and has more color options than conventional brick.