Australia could become one of the new centers of green metallurgy development thanks to its abundant renewable energy resources, including hydrogen, which can be individually adapted to different projects.

South Australia and Tasmania already have the capacity to meet most of their energy needs with green energy, according to Renew Economy.

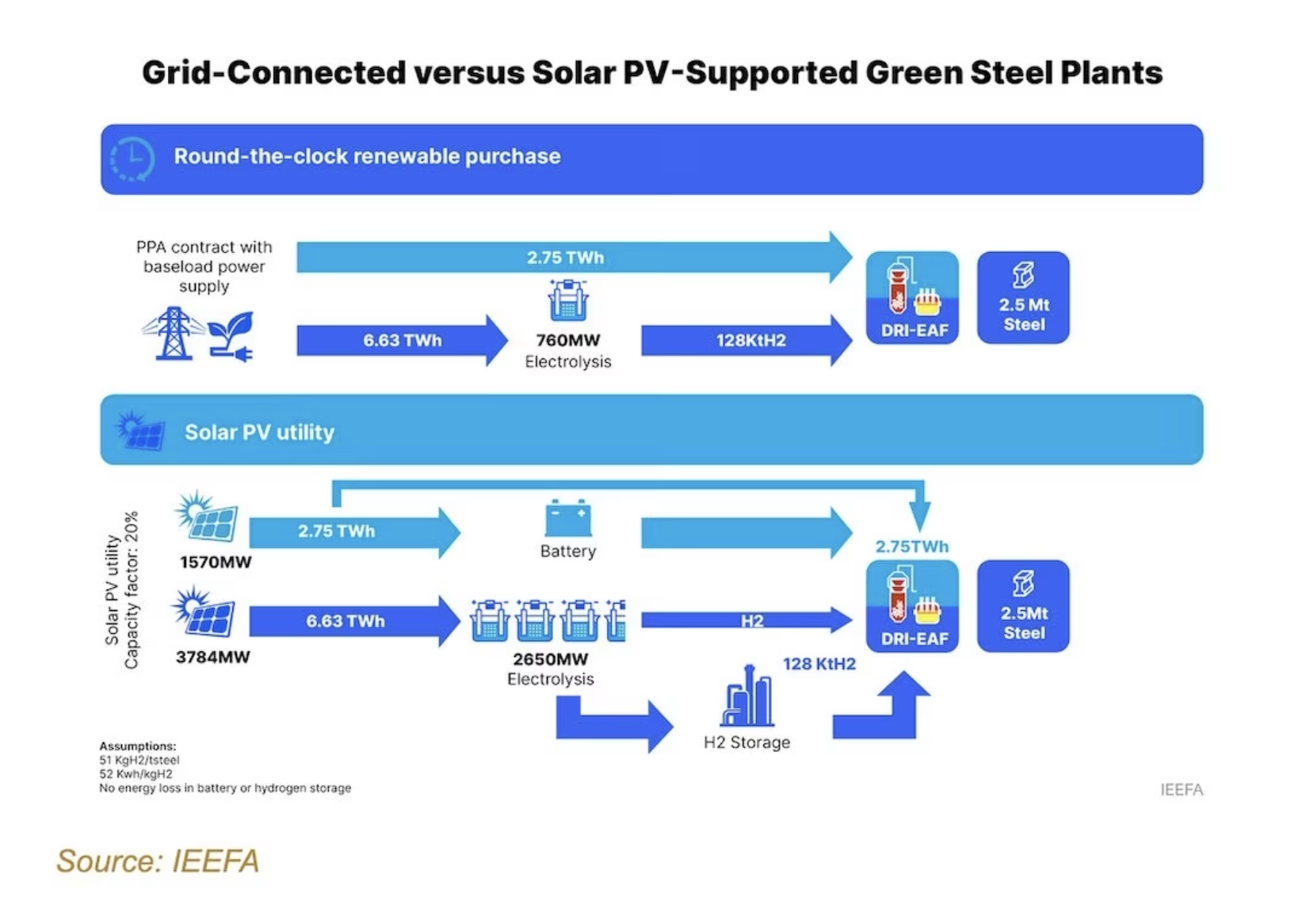

It is noted that the production of green steel using direct reduction electric arc furnace technology with low hydrogen leakage requires a significant amount of green H2 and continuous low-carbon electricity. In regions with abundant renewable energy resources, cheap green hydrogen could be produced in the future. But this requires significant investments in special solar and wind installations.

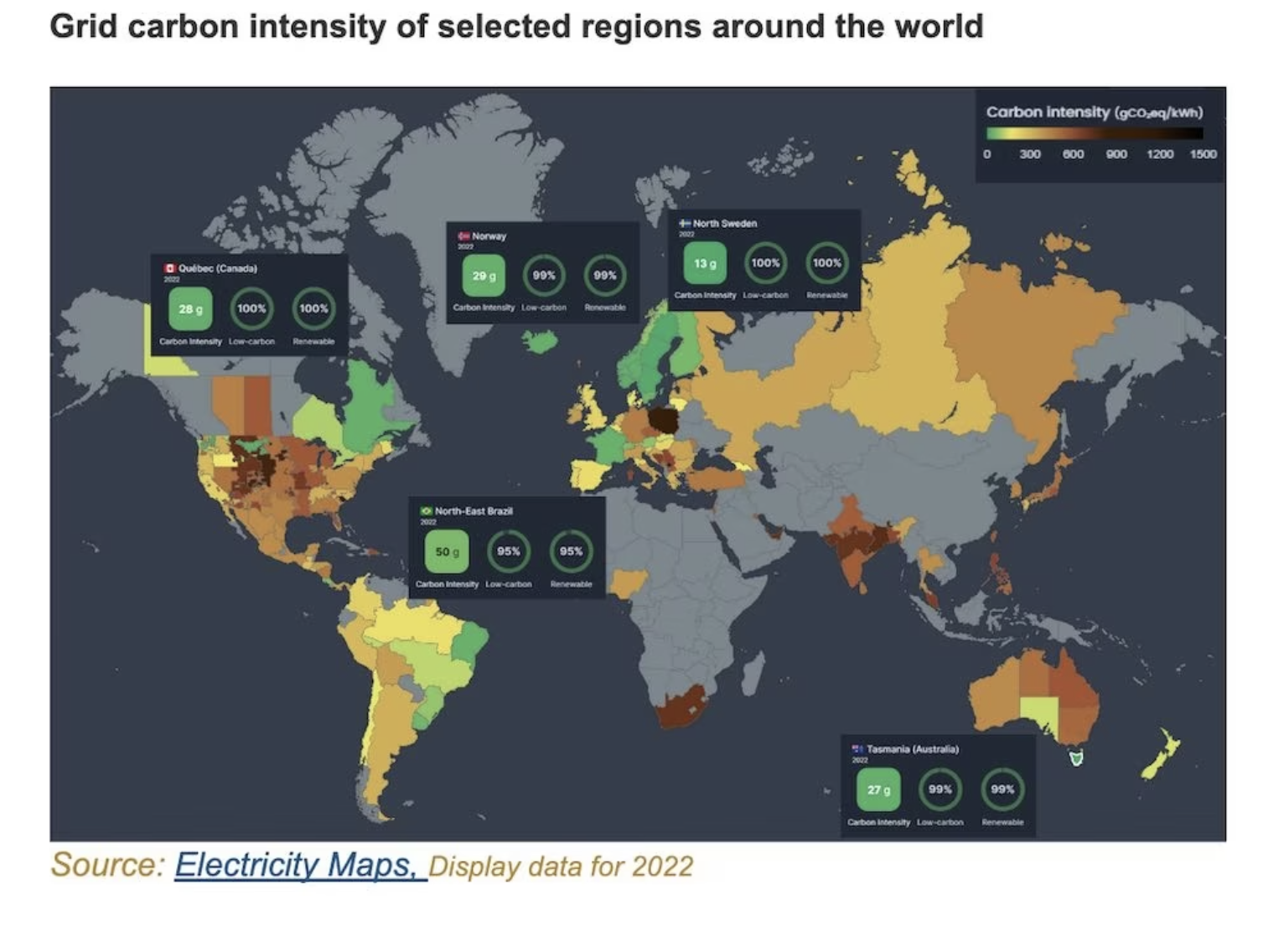

The article says that the need for continuous green energy encourages steelmakers to develop production in the short term in regions where such electricity is already available. For example, Norway, Brazil, Sweden, and the Canadian province of Quebec have powerful renewable energy and hydropower resources.

"For many years, location models have focused on minimizing the distance to end users or sources of raw materials, but now proximity to RES is shaping a new paradigm in the steel sector," Renew Economy said.

It is noted that the construction of new plants for the production of green steel in places with existing hydroelectric power plants is profitable, but it is not the final solution for the green transition of metallurgy. After all, the sources of hydropower, located near iron ore reserves, are limited, and the transition to green steel requires the development of solar and wind power plants and energy storage systems. Thus, for the production of one ton of steel using the H2-DRI-EAF technology, almost 3.6 MWh of electricity is required.

Research by the Minerals Research Institute of Western Australia (MRIWA) shows that an investment of about $3.6 billion is needed to expand renewable energy installations and batteries to produce 1 million tonnes of green steel. This exceeds the need for investment in flocculation, DRI plant, electric steel plant and even electrolyzers for hydrogen production.

It says that if the world meets the Global Promise to triple renewable energy production by 2030, it will allow for the production of green hydrogen to make low-carbon steel.

The article said that South Australia plans to achieve 100% green energy in the energy mix by 2030. In 2022, this indicator reached 70%, and during the week of October 2023 – 99.8%. Currently, some of the green energy is lost during low demand during the day, but it is planned to be used to generate hydrogen for the nearby Whyalla steelworks.

In addition, energy storage systems will be able to ensure uninterrupted delivery of hydrogen.

It is noted that Tasmania also has significant potential for the production of green steel, as it has reliable and powerful hydropower. The state has the potential to become a pioneer in the Australian production of green iron.

"Production of environmentally friendly steel is an energy-intensive process that creates a challenge for manufacturers," the article says. – It is expected that the transition to truly ecological steel with the use of ecologically clean hydrogen will begin in regions where the energy system is already dominated by the production of clean electricity."

Earlier, Ecopolitic wrote, that the Middle East and North Africa (MENA) region has significant potential for the production of green steel (DRI), particularly due to its significant solar resources for the production of renewable hydrogen.

As EcoPolitic previously reported, head of the environmentally friendly steel department of Primetals Technologies Oleksandr Fleishanderl said that there is no universal solution for the production of green steel and companies should combine the best possible solutions, in particular technologies for the transition to green hydrogen.