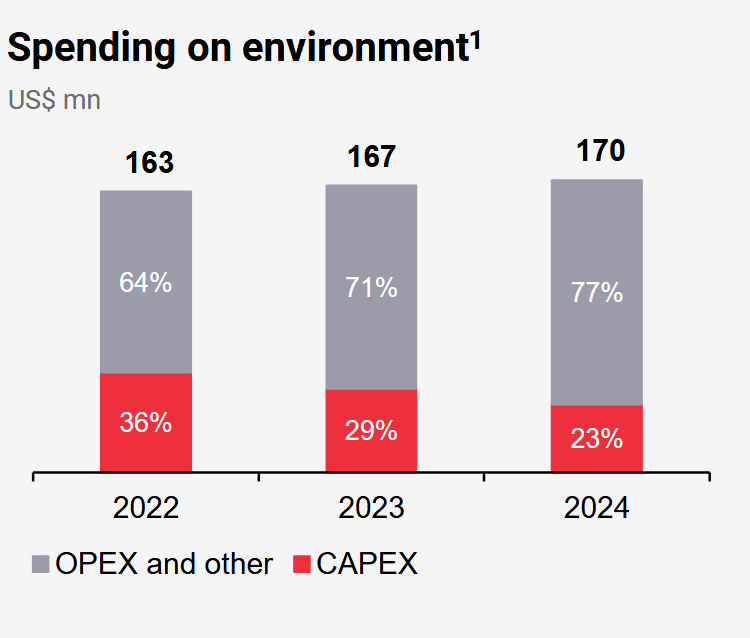

In 2024, Metinvest Group increased its environmental spending by 2% year-on-year to $170 million.

These figures are contained in the company's ESG (Environmental, Social, and Governance) report.

According to the report, Metinvest's investments in energy efficiency projects also increased by more than 50% last year, to about $17 million.

Metinvest's environmental costs during the years of full-scale war

Source: metinvestholding.com.

The company said that the increase in costs was due to production growth. In 2024, steel production increased by 5% and iron ore concentrate production by 42%.

This led to an increase in the environmental burden:

- air emissions increased by 5%;

- water intake – by 6%;

- waste generated – by 10%.

At the same time, the company noted that 92% of water was reused or recycled.

Metinvest also continues to develop its energy autonomy. For this purpose, the company is installing gas piston units and implementing plans to launch solar power plants.

As of the end of 2024, 15 of Metinvest's assets were certified according to the ISO 14001:2015 environmental standard and 7 were certified according to the ISO 50001:2011 energy management standard.

Thus, the company demonstrates a systematic approach to environmental management and a gradual transition to sustainable production even in wartime.

As a reminder, the European Union is actively introducing new non-financial reporting standards that radically change business requirements. Now, to operate in the European market, it is not enough for manufacturers to produce high-quality products. Under the new requirements, they must report on their environmental impact, social responsibility and corporate governance. Accordingly, Metinvest is actively preparing for this and is changing according to ESG principles.

Earlier, EcoPolitic told how the Ukrainian metallurgy was decarbonizing during the war.